COMPACT AND SOPHISTICATED HANDLING UNITS - MODULAR SYSTEM

ON THE MARKET FOR +40 YEARS

MADE IN GERMANY

STEADY REPETITION ACCURRACY

PROCESS RELIABILITY

APPROPRIATE FOR HARSH INDUSTRIAL ENVIRONMENTS OR DIFFICULT APPLICATIONS

Precision and durability for use in automation

Friedemann Wagner GmbH is a traditional German manufacturer of pneumatic handling units based on a modular system. Technically and qualitatively, they meet the highest demands of their renowned customers and prove that even small manufacturers can offer good solutions. Special design features set Friedemann Wagner apart from other solutions. Interkont Berger acts as Friedemann Wagner’s partner in Eastern Europe.

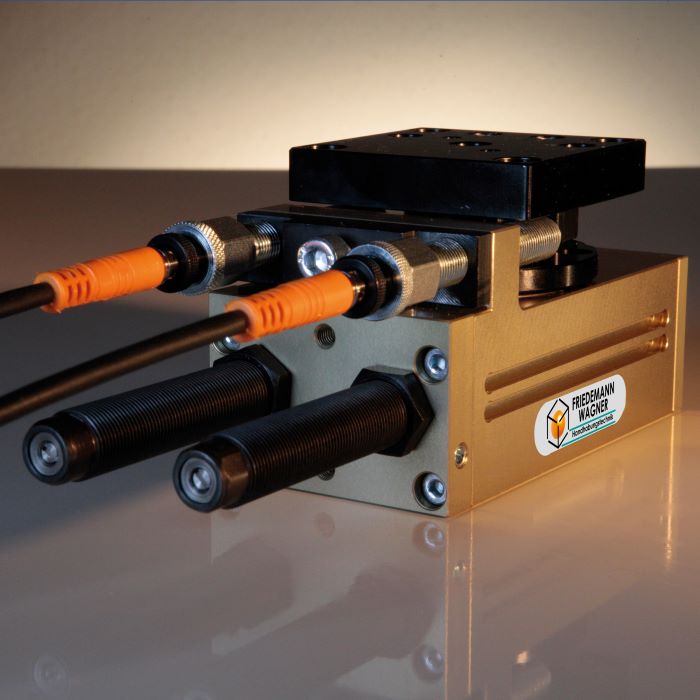

Handling units

PRODUCTS

They produce rotary indexing units and swivel units with a focus on rotary movements / lifting units and linear units with a focus on linear movements / gripper units with a focus on gripping movements. All units are pneumatically driven. Accessories: stop screws / screw-in columns / proximity switches / plugs, sockets, cables / hydraulic shock absorbers / connecting brackets, adapter and reduction plates as well as connecting pieces / centering rings.

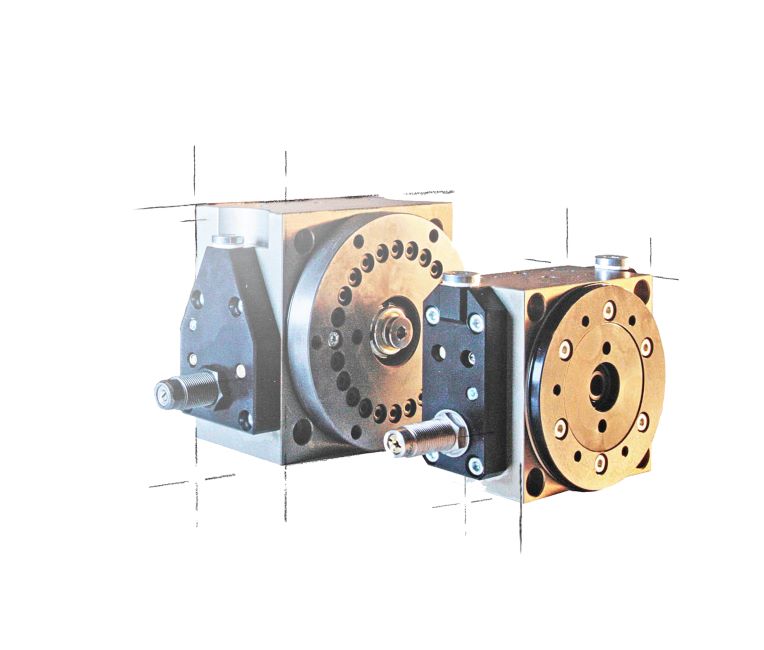

ROTARY INDEXING TABLES

- 4 sizes

- control via a 5/2 valve

- with hydraulic shock absorbers

- integrated choke for speed adjustment

- with pneumatic shock absorbers + with uneven partitions, e.g. 13, for RSE-6/RSE-9

SWIVEL UNITS

- external stops (full torque in end positions)

- swivel angle adjustable from the outside

- hollow stop screw (space-saving position for sensor)

- option: air and signal feed-throughs

- all interfering edges on one side

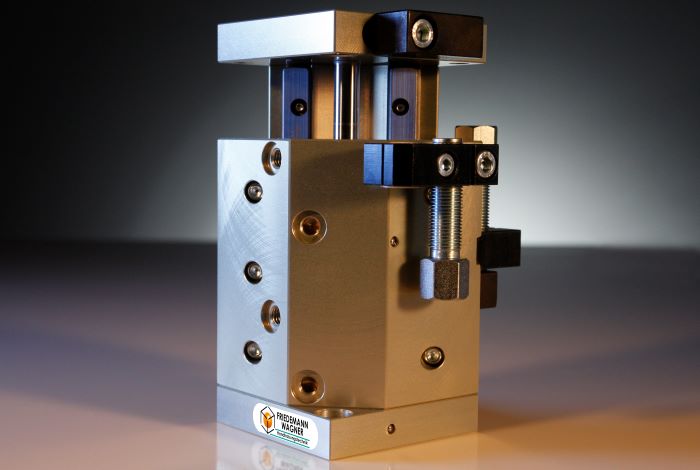

LIFTING UNITS

-

for vertical strokes

-

with cross roller guiding / absorbtion of high lift forces

-

also other versions: e.g. with ball riffles

LINEAR UNITS

-

individual cross roller guiding for absorbtion of high lift forces

-

house-own cross roller guidings reduce the installation width

-

enables the use of larger rollers → more load on a given construction frame

GRIPPING UNITS

- simple construction – reliable centering via central guiding piece

- various sizes available

- open principle: prevents dirt from accumulating (cleaning and degreasing possible when installed)

- query via inductive sensors

- depending on the product, gripping force protection possible (spring)

ACCESSORIES

- stop screws

- screw-in columns and tripods

- proximity switches

- plugs, sockets, cables

- hydraulic shock absorbers

- connection plates, reduction plates, adaptor elements, connection pieces and connection brackets

- centering rings

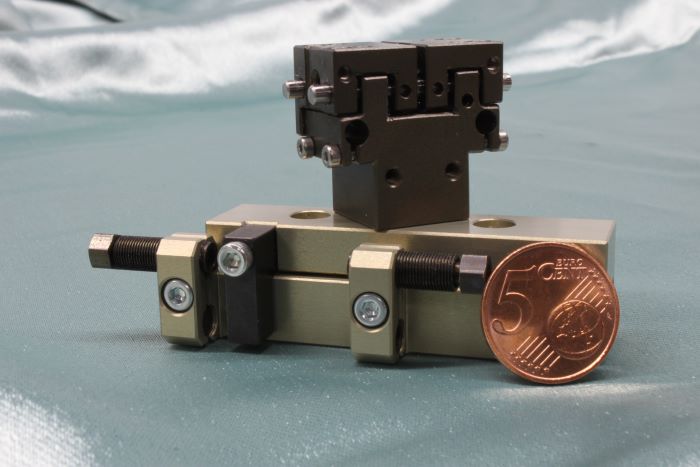

DWARFS OF FRIEDEMANN WAGNER

- for small workpieces

- low force

- less energy consumption

- narrow installation space

NEW PRODUCT

MANUALLY DRIVEN ROTARY INDEXING TABLE

- designed for manual or semi-automated workstations

- the plate with the workpiece attached to it is manually rotated into the end position by the production staff, where it automatically locks

- no external electric or pneumatic drive

- once the workpiece has been processed in the locked position, the rotary plate is unlocked pneumatically

- the plate of the rotary indexing table is released again with the unlocking for the next rotation

- the work process starts again from the beginning with the “next rotation”

- direction of rotation + partition changeable by the customer

- “end position” sensor query possible

FRIEDEMANN WAGNER

DOWNLOADS

All photos are the property of Friedemann Wagner.